LEGO Waffle Factory: Turning Breakfast Into a Technic Production Line

Share

How Brick Machines built a batter-to-plate waffle robot—and what you can learn to power your own food-themed factory MOCs

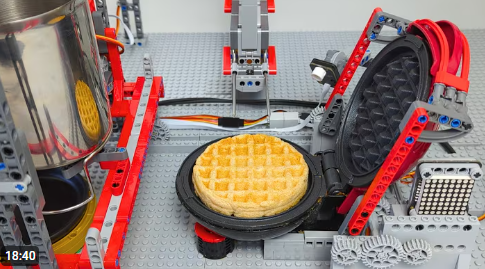

If you love the satisfying click of Technic beams and the smell of fresh waffles, this project is going to make your inner engineer and chef equally happy. In the featured video, creator Brick Machines showcases a fully automated LEGO Waffle Factory that handles nearly every stage of breakfast: measuring and mixing the batter, dispensing it into a real waffle iron, flipping/closing the iron, plating the finished waffle, and even drizzling syrup at the end. It’s a gloriously over-the-top Rube Goldberg breakfast line—an ode to motion control, sequencing, and clever use of Technic mechanisms working alongside non-LEGO hardware.

Beyond the delicious finale, what’s truly impressive is the system integration. The build blends LEGO Technic structures with programmable robotics (Mindstorms-style control), plus extra electronics and a few 3D-printed helpers where needed for interfaces and fixtures. That hybrid approach is the heart of many advanced “functional MOCs”: let LEGO handle structure, motion, and sensing, while off-the-shelf appliances do the hazardous jobs (heat, steam, sharp edges) safely and reliably. The result is a production cell that looks like something you’d see behind a café counter—only it’s built on studs, driven by gear trains, linear actuators, linkages, and carefully scripted timings.

From a learning standpoint, this waffle factory is a compact crash course in industrial design patterns: hoppers and feeders (for dry ingredients), dosing valves or timed pumps (for liquids), a mixing station (planetary or paddle motion), a transfer gantry (to deliver batter to the iron), a clamping/closing mechanism (levered arms with geared assist to operate the iron), a timed bake cycle, then a pick-and-place or conveyor stage to plate the waffle. The final touch—syrup dispensing—adds a classic end-of-line “finishing operation,” the sort of step manufacturers use for labeling, sealing, or decoration. That last flourish is also a perfect reminder that the magic of a factory MOC isn’t only in raw mechanics; it’s in sequencing: sensors (or encoder counts) telling the program when to start/stop each motion, building a rhythm the audience can follow.

Because the project interfaces with a genuine hot appliance, it also demonstrates best practices for safety-minded integration: use LEGO to actuate handles or buttons indirectly, keep ABS far from hot plates, mount electronics away from heat paths, and prefer food-safe contact parts where ingredients flow. In other words, treat the waffle iron like an industrial tool your robot operates—never as a LEGO component itself. That separation makes the build both impressive and practical, and it’s a pattern you can reuse across many kitchen-themed creations.

Tips for Building and Using This Technique

-

Modularize like a real factory. Split your build into cells: ingredient feed → mixing → dosing → cooking → plating → finishing. Build and test each cell independently before chaining them together with a central controller.

-

Choose the right actuators. Use large angular motors for clamping/lever motions (closing irons, pressing buttons) and linear actuators or worm-geared drives for precise, self-locking positions (great for syrup valves and hoppers).

-

Time your “recipes.” If you don’t have flow sensors, calibrate dosing by time × known flow rate. Log motor encoder ticks so you can repeat volumes consistently without weighing scales.

-

Guard against heat. Keep Technic frames at a safe distance from hot plates; add aluminum or silicone stand-offs where the robot must approach. Never let batter touch LEGO parts—route liquids through food-safe tubing/nozzles only.

-

Use sensors smartly. Color sensors can read marks on the iron to confirm open/closed positions; touch/limit switches can prevent over-travel; rotation counts can verify that a valve actually moved.

-

Design for cleanup. Make any part that gets near ingredients removable without tools. Smooth tiles beat exposed studs anywhere batter could splatter—wipe-down time matters.

-

Program in states. Think Idle → Load → Mix → Dose → Cook → Plate → Finish → Clean. A state machine simplifies debugging and makes emergency stops safer.

MOC Ideas You Can Build With the Same Factory Technique

-

Pancake or crêpe line: timed pour onto a griddle, automated spatula flip, fruit “dispenser,” and a chocolate-drizzle gantry.

-

Cookie decorator: conveyor indexes cookies under icing nozzles; turntable spins for spiral patterns.

-

Sushi conveyor: ingredient feeders assemble rice blocks and nori wraps, then a belt moves plated pieces around a loop.

-

Barista bot: actuator finger pushes espresso buttons; a rail positions cups under a milk frother; shaker adds cinnamon at the finish.

-

Egg-handling demo: gentle cradle and cam follower to crack/transfer eggs into a bowl (practice with ping-pong balls first!).

-

Candy sorter & packer: color sensor sorting, then a pick-and-place arm counts pieces into cups before sealing.

-

Breakfast “finishing cell”: independent syrup/butter dispenser you can dock onto any food line, powered by the same controller.

-

Dessert topping robot: a small XY gantry pipes frosting onto cupcakes with interchangeable star tips.

Whether you’re chasing the perfect Belgian waffle or the perfect demo of automation, this project proves the recipe is the same: modular design, precise actuation, careful sensing, and safety-first integration. Start with one cell—mixing, dosing, or plating—then grow your line. By the time your machine drizzles syrup on a plated waffle all by itself, you won’t just have breakfast…you’ll have a show.

Disclaimer: This article was created with the assistance of AI. While efforts have been made to ensure accuracy and originality, the content may include automatically generated text and should be considered as informational only.