LEGO Technic Taco Factory: Turning Gears into Guacamole

Share

Breaking down The Brick Wall’s automated taco machine—and how to build your own deliciously mechanical food-factory MOCs.

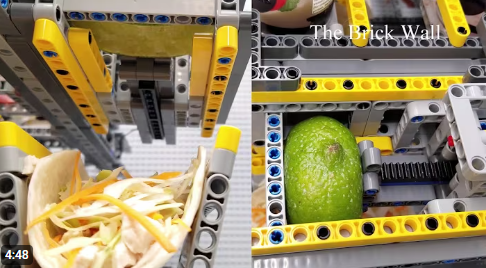

If you’ve ever watched a LEGO build and felt a craving coming on, you’re not alone. In LEGO Technic – TACO FACTORY, The Brick Wall serves up one of the most charming intersections of play and engineering: a motorized assembly line that builds tacos out of bricks. On screen, ingredients glide, flip, and drop in sequence; dispensers hiss (okay, whirr) to portion fillings; and a conveyor escorts each “taco” from station to station. It’s equal parts Rube Goldberg and restaurant line—only this kitchen is driven by gears, axles, chains, and clever timing. The video is short, but it’s packed with ideas you can lift straight into your next Technic project.

What makes the Taco Factory especially inspiring is the way it distills real-world automation into approachable LEGO modules. You can spot the key patterns instantly: a feeder that releases one item at a time, an indexing motion that advances the belt a fixed distance, and a set of synchronized mechanisms that operate only when the “taco” is in the right place. Those three ideas—feed, index, sync—are the backbone of almost any automated contraption, whether you’re simulating a kitchen or a car plant.

It helps that The Brick Wall has a whole “factory” vocabulary to draw from. Their channel is a treasure trove of playful production lines (pizza, tapas, wrapping, and more), all exploring the same family of mechanisms with different “recipes.” Browsing that catalog is like a masterclass in modular Technic design, timing, and throughput. If you liked tacos, you’ll love how they tackle other cuisines and concepts.

Under the hood, factory MOCs usually rely on familiar Technic fundamentals: gear trains to set speed and torque, linkages and cams to turn rotation into linear motion, and belts/chains to transport parts. Whether you power things with classic Power Functions, modern Powered Up, or high-output bricks such as BuWizz, the principles are the same—start with reliable motion, then layer on logic. (For a sense of scale in similar builds, The Brick Wall’s Tapas Factory description mentions a large array of PF motors and multiple BuWizz units, which shows how you can distribute power across modules when your line grows.)

If you’re new to Technic, don’t worry—this is exactly what Technic was built for: working mechanisms, gears, axles, and structures strong enough to host moving parts. LEGO’s own education materials even treat conveyors as a foundational exercise, because they teach controlled movement, sensing, and timing in one tidy package.

Tips: How to “Use” This Technique in Your Own Builds

-

Think in stations. Break the line into modules—shell prep, filling dropper, fold/press, outfeed. Design and test each one standalone, then join them with a conveyor.

-

Prototype with a hand crank first. Before adding motors, a crank helps you feel friction, binding, and timing errors.

-

Dial in speed with gearing. Most feeders need slow, high-torque motion while belts prefer steady medium speed. Use reductions and clutch gears to protect mechanisms.

-

Deliver one piece at a time. Use a cam, Geneva drive, or ratchet to create a precise “one-click, one-drop” action for ingredients.

-

Choose the right transporter.

-

Short lines: rubber tread belts or sliding pallets.

-

Longer lines/curves: Technic chain links with 1×3 liftarm paddles.

-

-

Guide the payload. Low side rails and gentle funnels stop parts from snagging; tile exposed surfaces so “food” glides smoothly.

-

Color = logic. If you add sensors (Powered Up / Mindstorms), color tiles can signal where to stop/operate—great for demos.

-

Power distribution. Big lines behave better with several small motors, one per module, rather than a single overworked drive.

-

Keep maintenance in mind. Build access hatches so you can clear jams and refill “ingredients” during shows.

-

Stagecraft matters. A menu board, minifig chefs, and a serving window turn a mechanism into a crowd-pleasing display.

MOC Ideas You Can Build with the Same Factory Technique

-

Sushi line: Rice base conveyor with rotating fish/veg droppers, plus a “nori” wrap station.

-

Burrito roller: Wider belt, end-stop that folds and “wraps” a tortilla plate around fillings.

-

Crepe maker: Turntable “griddle” with a cam-driven spreader arm and a topping carousel.

-

Sandwich stacker: Vertical magazine dispensers for bread, lettuce, cheese, etc., with a press station.

-

Dessert bar: Cookie base + frosting extruder (worm gear) + sprinkle shaker (eccentric cam).

-

Candy sorter-packer: Color sensor splits candies (1×1 rounds) into bins, then a carton loader cycles boxes through.

-

Tapas sampler: Multiple short belts feeding a central platter—each station contributes one bite. (A nod to The Brick Wall’s tapas build.)

-

Mini pizza line: Dough disk press, sauce dripper (slow worm gear), topping shutter gates, oven façade with light bricks.

-

Factory tour ride: Put seats on pallets and “process” minifigs through cartoon stations—pure theme-park fun.

-

STEM classroom kit: A compact conveyor plus a single feeder that students re-theme for different “products.”

The Taco Factory is more than a fun video—it’s a blueprint for modular, reliable motion that you can remix into any themed assembly line. Start small, keep your timing clean, and add personality with props and minifigs. When your demo runs for five minutes without a jam, you’ll know you’ve cooked up something special. Hungry for more? Rewatch LEGO Technic – TACO FACTORY and then tour The Brick Wall’s other “factory” builds for fresh mechanical ingredients. Bon appé-brick!

Disclaimer: This article was created with the assistance of AI. While efforts have been made to ensure accuracy and originality, the content may include automatically generated text and should be considered as informational only.