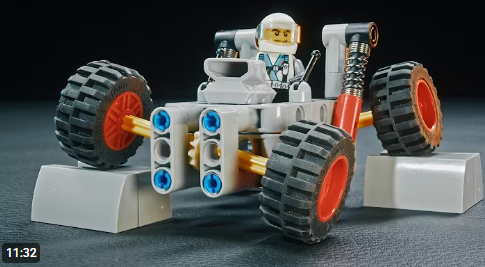

LEGO Technic Suspension Showdown: 11 Designs Put to the Treadmill Test

Share

What we can learn from DrEngine’s side-by-side suspension experiments—and how to use those tricks in your own MOCs

If you’ve ever built a LEGO Technic car and wondered why it hops like a rabbit over the slightest bump—or why your “off-road monster” bottoms out the moment it meets a carpet edge—today’s video lesson is gold. In #LEGO Suspensions Survive on the Treadmill — Making and Testing, the creator behind DrEngine constructs and compares 11 different suspension types, then runs them on a treadmill to expose strengths, weaknesses, and real-world behavior under continuous load. The format is simple but brilliant: identical test conditions, clear visuals, and repeatable motion that shows how each design copes with vibration, traction loss, and energy efficiency.

Why a treadmill? Because it transforms “static desk testing” into dynamic stress testing. Rather than rolling a few centimeters across a tabletop, each model endures constant motion, small oscillations, and the creeping resonance that reveals slop, binding, and poor damping. That’s where suspensions live or die: not in the first 10 cm, but in the next 10 minutes. By keeping speed and surface consistent, the treadmill acts like a wind tunnel for wheels—amplifying differences that would otherwise be easy to miss.

The lineup is a tour of Technic suspension thinking: from rubber-band stand-ins for coilovers to quirky linkages and even “weird” solutions using chains or leaf-spring analogs. Shorts tied to the full video tease drop tests and close-ups (and point back to DrEngine’s main breakdown), but the real value is seeing them endure sustained vibration. That’s when you notice which designs retain ride height, which introduce bump steer, which suffer from unsprung mass issues, and which simply shake themselves apart under harmonics.

For MOC builders, this is a rare apples-to-apples reference. Instead of guessing whether a double wishbone will behave better than a pendular axle for your next trophy truck, you can watch them fail (or shine) under the same conditions—and then choose accordingly. Even better, the treadmill test suggests tuning strategies: swapping spring rates (rubber bands vs. shocks), altering leverage ratios with anchor point changes, or adding anti-roll behavior via torsion elements. And because the video isolates the suspension variable, you can separate “chassis wobble” from true suspension dynamics—something that’s notoriously hard to judge when you’re also debugging steering geometry, gearing, and frame flex.

If you’re designing for play and display, this kind of evidence-based testing pays dividends. You’ll reduce part count where it doesn’t help, reinforce where it matters (axle bracing, hub support, shock mounts), and pick a geometry that matches terrain: fast carpet laps, smooth tabletop, or lumpy garden paths. Treat the treadmill like a design lens—once you’ve seen your suspension at speed, you’ll never tune blind again. A tweet circulating about the project even summarizes it succinctly: “11 Types of Suspensions for LEGO Technic — Making and Testing.” That’s the spirit—compare, learn, and iterate.

Tips: How to use (and tune) these suspension techniques

-

Match spring rate to mass. If the model sags, increase spring force (stiffer shocks, more rubber bands, or shorter leverage). If it pogo-sticks, soften it. Aim for ~30–40% static compression.

-

Control leverage. Moving the shock’s lower mount closer/farther from the wheel pivot changes effective stiffness and travel. Tiny anchor shifts = big feel changes.

-

Fight slop. Double-pin critical pivots, brace shock towers, and triangulate linkages. Slop becomes resonance on a treadmill—brace early.

-

Mind unsprung mass. Hubs, wheels, and outer gearing should stay light. Put gear reductions inboard when possible.

-

Tame bump steer. Keep steering link arcs sympathetic to suspension travel. Parallel control arms + correctly placed tie rods = steadier tracking.

-

Add roll control. For tall builds, consider torsion/anti-roll elements (liftarms under twist) to reduce lean without over-stiffening vertical compliance.

-

Test progressively. Start slow on the “treadmill” (conveyor belt, rolling mat, or gentle manual bench test), then increase speed and duration to expose weak points.

-

Serviceability first. Make shocks/bands easy to swap so you can iterate quickly.

Ideas: MOCs that benefit from these suspension styles

-

Trophy trucks & rally cars: Long-travel double wishbones up front, live/panhard rear—tuned for fast, chattery terrain.

-

Rock crawlers: Pendular or multi-link solid axles with soft rates and generous articulation.

-

Desert buggies: Lightweight double wishbone all around with progressive leverage for big hits.

-

Half-tracks & bogie systems: Leaf/elastic “walking beam” bogies to keep treads planted over obstacles.

-

Articulated haulers: Central pivot + compliant axles to track uneven ground.

-

Compact Speed Champions-scale customs: Micro-struts or rubber-band mini wishbones for believable stance without bulk.

-

Robotics demos: Sensor-equipped rigs to log oscillation, pitch/roll, and wheel slip as you swap suspension modules.

-

Display dioramas with motion: Slow-rolling loops where viewers can see suspensions work continuously—museum-style education pieces.

-

Test mules: Dedicated chassis with quick-release modules so you can A/B suspension ideas in minutes.

-

Weird mechanics experiments: Chain “springs,” rubber leaf packs, and other unconventional flex elements inspired by the video’s more experimental entries.

DrEngine’s treadmill experiment is the kind of practical, side-by-side science our Technic hobby needs: clear conditions, honest results, and plenty of inspiration to try new geometries. Whether you’re building a rock crawler that mooches over bumpy garden stones or a sleek rally car that devours carpet laps, let these 11 suspension types guide your next prototype—and don’t forget to test dynamically before you lock in the design. Build, tune, run it “on the belt,” and iterate. Your MOC will drive better, look smarter, and survive longer. Happy building!

Disclaimer: This article was created with the assistance of AI. While efforts have been made to ensure accuracy and originality, the content may include automatically generated text and should be considered as informational only.