LEGO Drone: Making a Quadcopter with LEGO Motors & Propellers

Share

What the video proves, how it works, and ways you can use this propulsion technique in your own MOCs

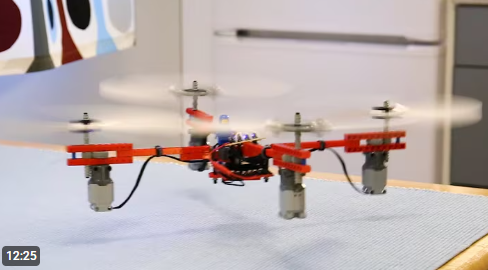

Every LEGO fan has wondered at some point: can bricks actually fly? Not a swooshable starfighter on a display stand—but a real craft that lifts off the ground under its own power. The YouTube clip “Making a Drone with Lego Motors and Propellers” answers with a bold yes, documenting a quadcopter whose frame, motors, and propellers are all LEGO—augmented by the essential non-LEGO electronics that make modern drones possible.

The build demonstrates a few key truths. First, LEGO components are stronger and more capable than most of us assume—especially Technic liftarms, axles, gears, and the official LEGO propellers—which can be arranged into a rigid, lightweight airframe. Second, while the airframe and drive hardware can be LEGO, you still need a battery, a radio receiver, and a flight controller to stabilize and command the four rotors; that’s how virtually all quadcopters maintain balance and respond to input by modulating motor speeds hundreds of times per second.

The video’s methodical approach is what makes it so compelling for builders. Before committing to a final craft, the creator iterates through propeller and motor choices and explores gearing to reach practical thrust. Reports summarizing the project note that LEGO L-motors, geared about 1:1.67 to spin the props faster, offered a workable mix of thrust versus mass—on the order of ~120 g of continuous thrust per rotor in the tested setup. Details like those help translate “cool idea” into “repeatable technique.”

There’s also a valuable engineering mindset on display: measure, change one variable, measure again. The airframe uses symmetrical geometry to keep the center of mass centered; the props are spaced to minimize aerodynamic interference; and wiring/battery placement is balanced so the flight controller doesn’t have to fight unnecessary bias. If you’ve ever tried to get a Technic vehicle to drive straight, you already know why that matters—now multiply it by three axes and put the whole thing in the air.

Two caveats worth calling out. First, some community discussion around LEGO-based drones notes that experimenters sometimes push motors beyond typical operating voltages to achieve enough lift; that can shorten component life and isn’t recommended if you want a long-lasting model. In other words, understand the limits of your parts and choose your goals accordingly.

Second, actual flight places your creation under model-aircraft/UA regulations in your country; even a tiny build must be flown safely and legally. Keep it line-of-sight, away from people and property, and know your local rules.

So what’s the “technic” you can borrow from this build? Think of it as LEGO propulsive thrust: using LEGO motors and propellers (or rotor blades) to move air efficiently, paired with a smart structure that’s stiff, light, and balanced. Whether you aim for a real hover with non-LEGO electronics, or for ground/water vehicles powered by airflow alone, the same design patterns show up: rigid frames, low friction drivetrains, careful mass budgeting, and good prop selection. With that mindset, you’re ready to try your own experiments—flying or otherwise.

Tips: how to use this technique in your own builds

-

Start with a rigid, square frame. Use Technic liftarms in triangles and X-braces. Even tiny flex ruins flight stability (and wastes thrust).

-

Balance the mass budget early. Weigh the airframe, each motor/prop module, battery, and electronics (if used). Aim for a thrust-to-weight ratio >2:1 for comfortable control.

-

Keep drivetrains simple. If you must gear up, minimize backlash and use fresh axles/bushings to reduce friction and heat.

-

Propellers matter. Larger diameter = more thrust at lower rpm, but also more torque and frame loading. Test what your motors can actually spin. Document your measurements.

-

Mind motor cooling. LEGO housings are plastic; continuous high load generates heat. Leave airflow gaps around motors and avoid enclosing them tightly.

-

Lock in symmetry. Place arms, props, and electronics so the center of mass is exactly at the craft’s geometric center and on the prop plane.

-

Vibration control. Add tiny rubber elements or flexible bushings between the flight controller and the frame (if flying) to help the gyro read cleanly.

-

Power sanity. Stay within manufacturer voltage specs for longevity; if you experiment above that, understand the risks (shorter motor life, melted housings).

-

Electronics setup (if flying). A lightweight flight controller (Betaflight-class) with a matching receiver is standard; that’s how quadcopters modulate four rotor speeds to pitch/roll/yaw.

-

Test tethered first. Use a soft tether or hand-catch rig to observe behavior at partial throttle before free flight. Safety glasses are not optional.

Ideas: MOC types that use this propulsion technique

Aerial (with non-LEGO flight electronics):

-

Micro LEGO Quadcopter: Minimal 2× liftarm arms, L-motors + official props, ultralight stack and small LiPo. Bench-test thrust, then refine.

-

Tilt-Rotor VTOL: Two big rotors mounted on Technic tilting nacelles; hover like a quad, transition to forward flight with tilt servos.

-

Octo “Heavy-Lift” Trainer: Redundant rotors for smoother control and extra payload (a tiny camera brick, not a real camera).

Ground & water (LEGO-only motion, no flight electronics):

-

Airboat: A flat Technic raft with a shrouded LEGO propeller at the stern. Great for bathtubs and smooth floors.

-

Hovercraft-on-casters: Use props to generate forward thrust while the chassis rides on hidden wheel bogies (the illusion feels “hovering”).

-

Fan-Powered Racer: A minimal car pushed by a rear prop, teaching thrust vs. drag and steering with fins.

-

Wind-Tunnel Rig: Build a simple duct and a thrust scale to compare LEGO propellers, gears, and rpm—just like the video’s test-led approach.

Display & education:

-

Cutaway Quadcopter Model: Non-flying, but shows drivetrain, props, and where a flight controller/battery would go—perfect for classrooms.

-

Stabilization Demo Rig: Suspend a frame on gimbals and spin props with variable speed to feel how changing rotor speeds creates pitch/yaw/roll.

-

Blimp Hybrid: Use LEGO motors/props for thrust and steering with a helium envelope for lift—a classic STEM crowd-pleaser.

LEGO won’t replace carbon-fiber racing drones any time soon—but that’s not the point. This technique is about exploring real aerodynamics and control with the world’s most approachable building system. Use the video as your launchpad: build light, brace well, measure honestly, and keep safety first. Whether you craft a true hovering quadcopter or a fan-powered boat that skims across the kitchen floor, you’ll be practicing the same core idea—turning spinning plastic into directed airflow and motion. And that’s a beautiful kind of LEGO magic.

Disclaimer: This article was created with the assistance of AI. While efforts have been made to ensure accuracy and originality, the content may include automatically generated text and should be considered as informational only.