The World’s Strongest LEGO “L-Motor” Concept — How to Build, Brace, and Use Extreme Torque in Your MOCs

Share

Inspired by Brick Science’s over-the-top motor pack, this guide shows how stacked motors and smart gearing can turn one output axle into a monster of controlled torque—plus practical tips and project ideas.

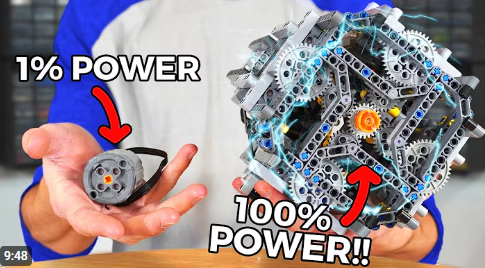

Every LEGO Technic fan eventually asks the same question: how do I squeeze more power out of my build without shredding gears or tripping battery protection? In the video “I Made The World’s STRONGEST LEGO L-Motor!!”, creator Brick Science tackles that problem the gloriously fun way—by bundling multiple LEGO motors and battery boxes into a reinforced gearbox that feeds one output like a supersized “L-motor.” The result isn’t a single stock motor; it’s a motor pack that concentrates the torque of several units through carefully chosen reductions and heavy bracing so the output axle behaves like an absurdly strong drive source.

At a high level, the idea is simple: combine the torque of several motors and control it with gearing and structure. In practice, success depends on three things:

-

Gear ratio strategy. You want reductions early (close to each motor) to keep torque per axle manageable, then merge power into a common shaft. Over-gearing for speed causes gear skip; under-gearing wastes potential. LEGO’s spur/double-bevel families make it easy to stage tidy 3:1 and 5:3 steps, while worm gears are best saved for locking or compact final reductions due to efficiency loss.

-

Rigid framing and load paths. Torque tries to twist everything. 5×7 frames, perpendicular connectors, and triangulated liftarms prevent flex that leads to gear disengagement (“popping” under load). Splitting gear stages across parallel planes and tying them with frames keeps meshing consistent even when current surges.

-

Electrical sanity. Multiple motors draw serious current. Spreading load across more than one battery box, using short, low-resistance wiring runs, and watching thermal/overcurrent cutoffs keeps the party going. Brick Science’s build highlights exactly that mindset: plenty of motors, plenty of power sources, and a gearbox that doesn’t explode when you actually use it.

Think of this approach as creating a drop-in power module for your heaviest MOCs—crawlers, cranes, winches, presses, and amusement rides—where a normal L or XL motor stalls. Instead of risking brittle axles or stripped 12-tooth gears, you design the drivetrain around a controlled torque source: reductions that protect the weakest link, bracing that locks alignment, and a power budget that your electronics can actually deliver. If you’ve ever watched your carefully built gearbox chatter, skip, and die under a climb or lift, you’ll immediately see why this technique is so appealing. It’s not just about “more”; it’s about usable power—torque that arrives at the wheels, hook, or drum without self-destructing the model. And once you’ve built one strong, compact motor pack, you can reuse it across projects like any other subassembly—swap the output orientation, tweak the final ratio, and you’re off to the races (or the rock face). For a concise summary of the concept—multiple motors feeding optimized gear trains for maximum torque—see the description/summaries circulating about the video’s premise.

Tips for Building and Using a “Super L-Motor” Pack

-

Stage reductions early. Start with a modest reduction (e.g., 20:12 or 24:8 equivalents) right after each motor before merging outputs; it lowers stress on shared axles and gears.

-

Brace like a bridge. Use 5×7 frames, perpendicular connectors, and liftarm triangles around every meshing pair. If you can squeeze a gear by hand and see daylight change, add bracing.

-

Short, supported axles. Avoid long unsupported spans; add bushings or frames every 3–5 studs to stop torsional wind-up.

-

Center the load. Place the output shaft near the frame’s neutral axis; asymmetry invites flex and skipping under shock loads.

-

Clutch wisely. Consider a 24t clutch gear upstream as a “fuse” to protect gear trains during stalls and crashes.

-

Parallel power. If you use many motors, split them across multiple battery boxes/ports to reduce voltage sag and thermal trips.

-

Mind efficiency. Prefer spur/double-bevel reductions for the main stages; reserve worm gears for locking/final reduction where their back-driving resistance is an advantage.

-

Test under load. Bench-test with a brake (pinch the output wheel, lift a weight) to listen for skip and watch for twisting frames—then reinforce those points.

-

Gear mesh alignment. Keep gears fully engaged and square; half-tooth meshing or bent axles will nuke teeth under big torque.

-

Thermal breaks. In long sessions, give electronics cooldown windows; continuous stall is the fastest route to shutdowns.

MOC Ideas That Shine With This Technique

-

Extreme rock crawler with portal hubs and ultra-low final drive for near-vertical climbs.

-

Heavy crane or derrick that can actually lift and hold loads without droop.

-

Rescue tow truck with a serious under-lift and a no-nonsense winch drum.

-

Drawbridge/portcullis where a compact motor pack hides in the tower and handles counterweight shifts.

-

Industrial press or crusher (use foam/soft materials!) to demonstrate torque safely.

-

Snowplow/bulldozer pushing dense piles instead of just fluff.

-

GBC conveyor or spiral lift that runs heavy balls/bricks without stalling.

-

Theme-park drop/hoist ride with a confident lift and smooth braking.

-

Tracked vehicle (tank/dozer) that pivots in place on rough surfaces without brown-outs.

-

Elevator platform for stage displays—silent gearing + clutch gear as a safety.

Turning a handful of standard LEGO motors into a single torque-dense power module is a game-changer for ambitious Technic builds. The Brick Science “strongest L-motor” concept shows that with the right gear ratios, ruthless bracing, and sensible power distribution, you can move from fragile prototypes to reliable, heavy-duty mechanisms that feel industrial. Start small—build a compact, well-braced gearbox with two motors, prove it under load, then scale to three or four. Treat the unit like a reusable subassembly and you’ll quickly find yourself dropping it into crawlers, cranes, and winches like a pro. When power, structure, and electrics work together, your MOCs stop stalling and start performing.

Disclaimer: This article was created with the assistance of AI. While efforts have been made to ensure accuracy and originality, the content may include automatically generated text and should be considered as informational only.